Industry-University-Research Cooperation and Exchange

2024-11-29 09:12

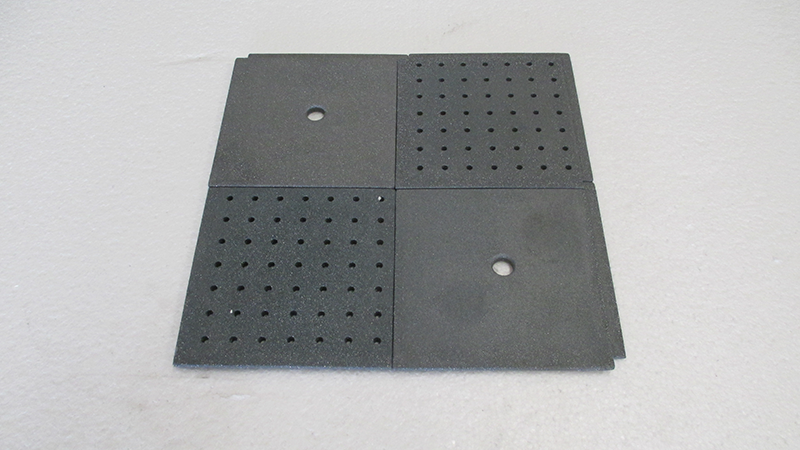

Shenyang Starlight Advanced Ceramics Co.,Ltd has always insisted on continuous research and development and innovation of technology, and have maintained close cooperation with major universities and research institutes for many years. This time, we were fortunate to invite professor Ru from Northeastern University to come to our company for academic exchanges with us and answer our questions about the problems that arise in the actual silicon carbide production process.

The significance of academic discussion is not only to improve the process and quality of our silicon carbide products, but also to continuously explore new possibilities through communication with professors, and to generate inspiration in the field of silicon carbide through communication.

It is not advisable to remain unchanged in the silicon carbide production process,so we must constantly learn from the outside world, learn new knowledge and theories, and continue to study and practice to seek new breakthroughs. In this way, whether it is to reduce costs and increase efficiency or to improve the silicon carbide production process, there will be feasible ways and methods.

Silicon carbide epitomizes unparalleled excellence in high-performance materials, distinguished by its exceptional thermal conductivity (≈120–490 W/m·K), ultrahigh hardness (~25 GPa), and intrinsic resistance to thermal degradation up to 1,650°C in inert environments. Its negligible thermal expansion (4.0×10⁻⁶/K) ensures dimensional stability under extreme thermal cycling, while superior chemical inertness against acids, molten metals, and oxidizing agents underpins longevity in corrosive settings. SiC’s wide bandgap semiconductor properties (3.3 eV) further enable breakthroughs in high-voltage electronics and optoelectronics. Coupled with radiation resistance and low density (3.21 g/cm³), SiC emerges as the quintessential material for aerospace, nuclear, and next-gen energy systems demanding efficiency, durability, and precision.

Our technicians consulted the professor based on the problems that arise in the actual production process of recrystallized silicon carbide, reaction-sintered silicon carbide, and silicon nitride combined with silicon carbide. The professor started with the characteristics of materials science such as atomic particle density, and then integrated the problems that may be encountered in the actual production process and which elements affect the density of the green body, porosity, material ratio, and base ratio, and answered them one by one. Through this communication and discussion with the professor, we will continue to try to optimize the existing formula and process flow, and strive to improve the product process to better serve our customers.

Get the latest price? We'll respond as soon as possible(within 12 hours)