Semiconductor Products Seminar

2025-01-24 08:42

Shenyang Starlight Advanced Ceramics Co,.Ltd have been focusing on silicon carbide products for more than 30 years and have been working on the development of silicon carbide materials in new fields.As a pioneering enterprise in the field of Silicon Carbide and semiconductor materials, convened a seminal seminar to deliberate on the intricacies of semiconductor sample production. The event, held at the company's state-of-the-art conference hall, brought together an esteemed gathering of department heads, technical experts, research scientists, and production managers, all united by a shared vision to propel the boundaries of semiconductor technology.

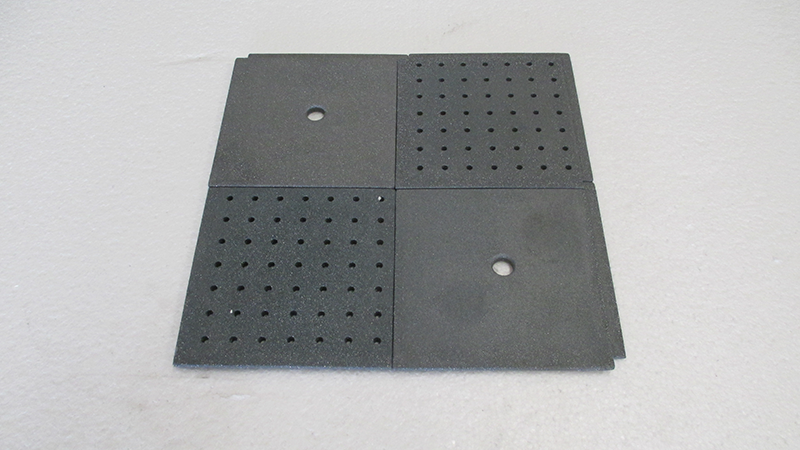

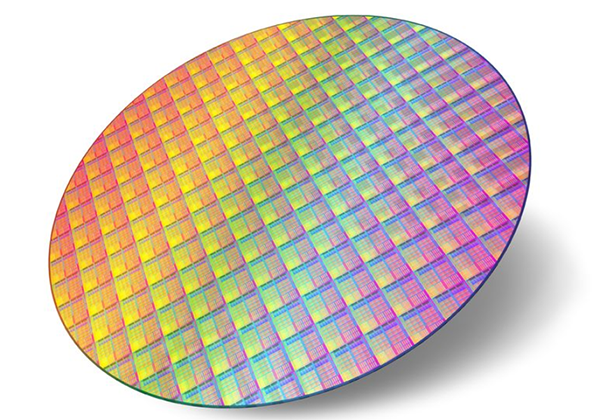

In recent years, silicon carbide materials have a new application in the semiconductor industry.As a third-generation new semiconductor material, silicon carbide products have outstanding performance in crystal boats, cantilever propellers and other Silicon Carbide products.

We are actively seeking cooperation with chemical vapor deposition manufacturers to provide the Silicon Carbide green body, they will complete the subsequent coating work, and then together we will provide the final Silicon Carbide product to the customer to expand our semiconductor industry market.For this cooperation, we specially convened all the personnel of the relevant departments to meet and discuss how to control the details from the source of production, be sure to control each link in place, and strive to make the most perfect product to cooperate with our partners.

The discussion then shifted to the challenges faced in semiconductor sample production. Mr. Wang, the Production Manager, elaborated on the complexities involved in the manufacturing process, including the need for precise control over material composition, temperature, and processing conditions. "Even the slightest deviation can result in defective samples, impacting performance and reliability," he noted.

Ms. Liu, the Quality Control Supervisor, added that ensuring consistent quality across different batches was another significant hurdle. "With the miniaturization of semiconductor components, the tolerance for errors has shrunk dramatically," she said. "Our quality control measures must be as meticulous as the production process itself."

All the participants actively put forward their own opinions and suggestions, and the meeting also determined the main direction of cooperation in the future, and I believe that through the efforts of all of us, we can achieve a successful result.

Get the latest price? We'll respond as soon as possible(within 12 hours)