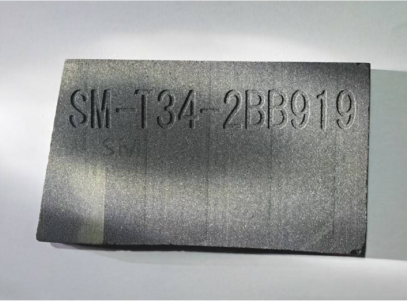

Three-coordinate detection

Shenyang Starlight Advanced Ceramics: Three Decades of Precision Manufacturing Excellence in Silicon Carbide Solutions

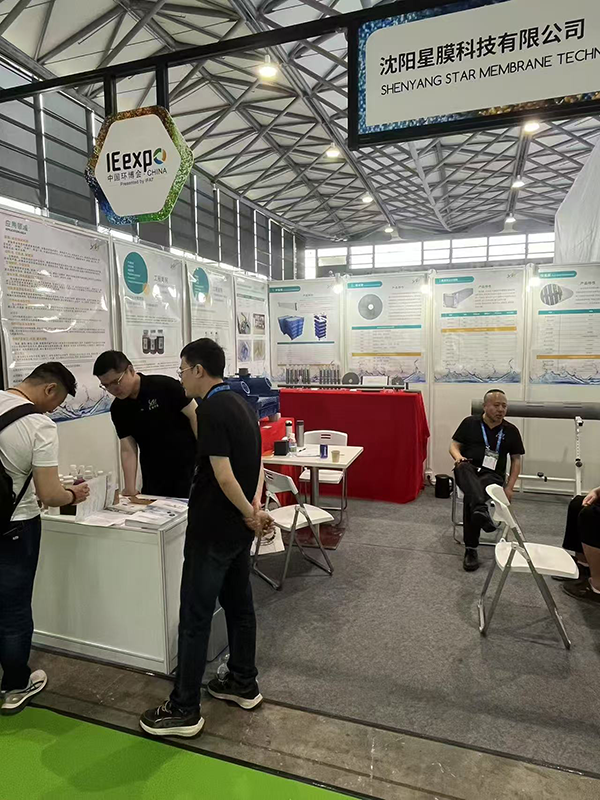

For over 30 years, Shenyang Starlight Advanced Ceramics Co., Ltd. has stood at the forefront of silicon carbide manufacturing, delivering high-performance ceramic solutions to more than 2,000 satisfied clients worldwide. Our unwavering commitment to silicon carbide quality and precision has established us as an industry leader in advanced ceramic components.

Precision Manufacturing Capabilities

At the heart of our operation lies a state-of-the-art quality control system featuring:

Advanced Three-Dimensional Measurement Technology

Multiple high-precision coordinate measuring machines (CMM)

Measurement accuracy up to ±0.5μm

Full-surface scanning capability for complex geometries

Automated data collection and analysis systems

Comprehensive Quality Assurance Process

Silicon carbide raw material inspection with spectrometers and microscopes

In-process dimensional verification at critical silicon carbide production stages

Final product certification with complete traceability

Customized testing protocols for specialized applications

Technical Expertise and Industry Applications

Our three decades of experience have enabled us to develop specialized solutions for:

Semiconductor Equipment Components

High-purity SiC parts for wafer processing

Plasma-resistant components for etching systems

Thermal management solutions for deposition equipment

Industrial Heating Systems

High-temperature kiln furniture

Energy-efficient radiant tubes

Custom-designed heating elements

Mechanical Seals and Bearings

Wear-resistant SiC seals for pumps

High-load bearing components

Corrosion-resistant industrial parts

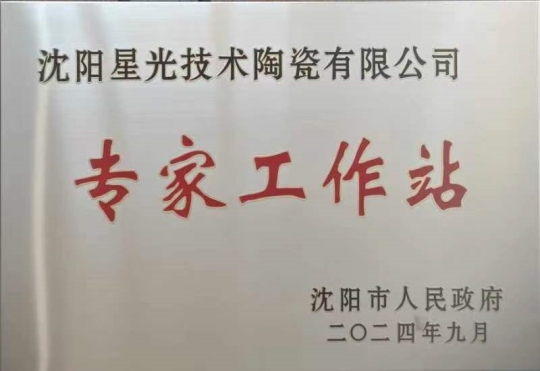

Quality Management System

We maintain rigorous quality standards through:

ISO 9001:2015 certified manufacturing processes

Statistical process control methods

Continuous improvement programs

Employee quality training initiatives

Customer-Centric Approach

"Our success comes from understanding that our clients' requirements are constantly evolving," says Mr. Wang, our Quality Control Director. "That's why we've invested heavily in precision measurement technology - to ensure every component we deliver meets exact specifications, every time."

Recent Technological Advancements

In 2024, we further enhanced our capabilities with:

New optical measurement systems for surface finish analysis

Upgraded CMM software for improved data visualization

Automated reporting systems for faster quality documentation

Enhanced calibration procedures for measurement equipment

Why Customers Choose Shenyang Starlight

30 years of specialized silicon carbide manufacturing experience

2,000+ successful client partnerships

99.8% on-time delivery rate

<0.1% quality rejection rate

24/7 technical support availability

Future Development Plans

Looking ahead, we are committed to:

Expanding our metrology laboratory capabilities

Implementing AI-assisted quality inspection

Developing new high-performance silicon carbide grades

Enhancing our global technical support network

Testimonials from Satisfied Clients

"Working with Shenyang Starlight has transformed our supply chain reliability," noted a senior engineer from a leading semiconductor equipment manufacturer. "Their dimensional consistency and quality documentation are unmatched in the industry."

Get the latest price? We'll respond as soon as possible(within 12 hours)