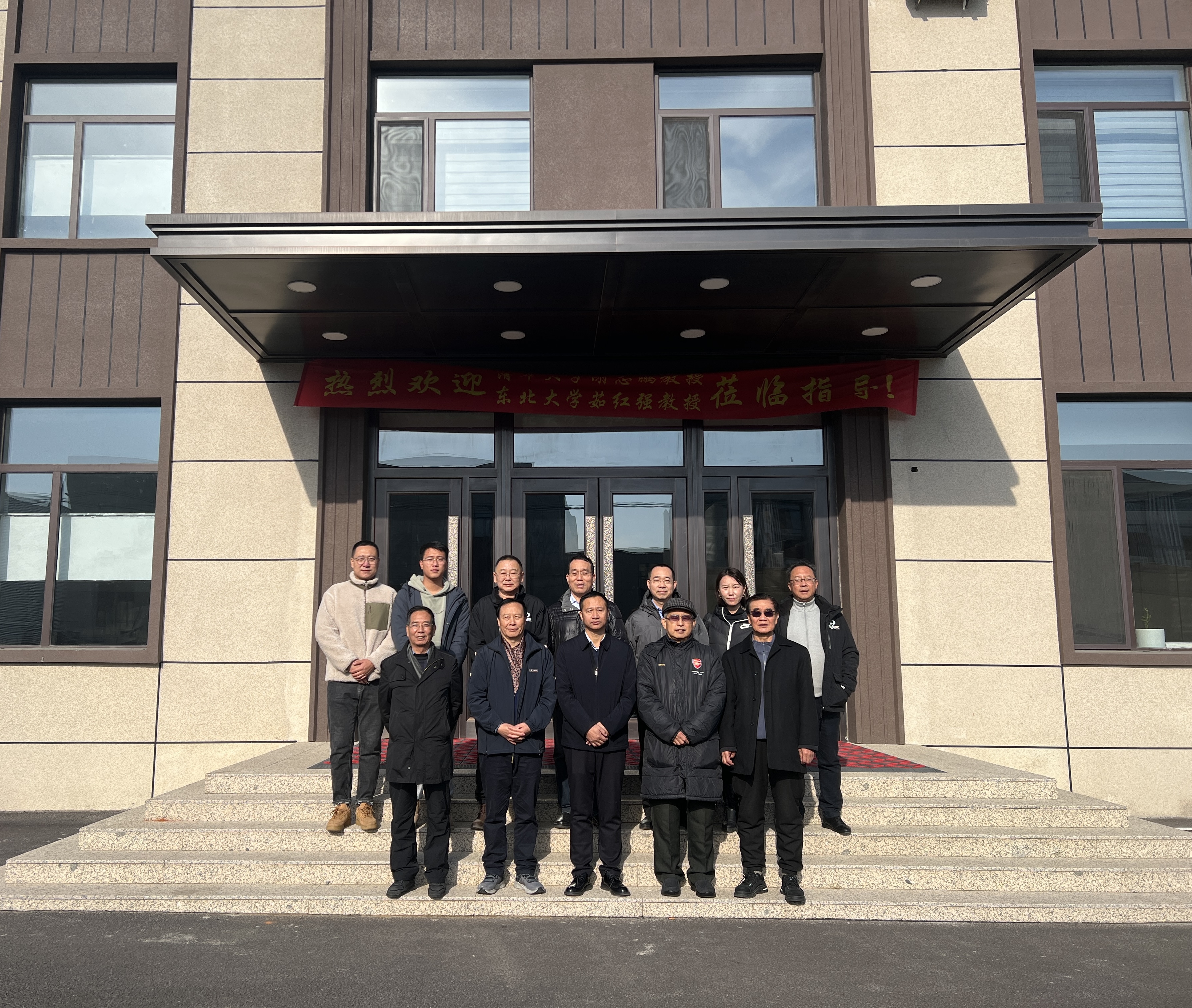

Exchange and cooperation with scientific research institutions

We have been working with professionals in the professional field to explore the unknown possibilities of silicon carbide materials and the development of their applications. Recently, Professor Xie from Tsinghua University, Professor Ru from Northeastern University, and Dr. Wang and Dr. Tang from the Institute of Metal Research, Chinese Academy of Sciences, visited our company for cooperation and exchange.

1. Academic-Industrial Synergy: Bridging Theory and Practice

The three-day technical summit hosted at our R&D center facilitated deep-dive discussions on overcoming longstanding challenges in Silicon Carbide commercialization. Professor Xie, a pioneer in ceramic matrix composites, shared his team's latest findings on grain boundary engineering – a revolutionary approach to enhance Silicon Carbide's thermal shock resistance through controlled crystal orientation. "By aligning β-Silicon Carbide grains along the crystallographic direction," he demonstrated through atomic-scale modeling, "we can theoretically increase fracture toughness by 40% without compromising thermal conductivity."

Complementing this theoretical framework, Dr. Wang from IMR presented experimental data from their 2,500°C ultra-high temperature sintering trials. Their patented multi-stage recrystallization process achieved unprecedented density levels (≥99.2% TD) while reducing residual silicon content to <0.3% – critical for minimizing high-temperature deformation in semiconductor applications. Our production team immediately prototyped these parameters, observing a 15% improvement in wafer support plate flatness during subsequent CVD tests.

Professor Ru's contribution focused on industrial scalability, addressing the historical cost barriers of Recrystallized Silicon Carbide manufacturing. His team's computational fluid dynamics (CFD) model optimized our gas diffusion furnaces, reducing argon consumption by 22% during the critical recrystallization phase. Meanwhile, Dr. Tang's surface modification techniques using plasma-enhanced chemical etching successfully increased Recrystallized Silicon Carbide's oxidation resistance threshold from 1,400°C to 1,550°C in oxidative atmospheres, a breakthrough for aerospace thermal protection systems.

2. Technical Superiority of Next-Gen RSiC Plates

2.1 Thermal Management Revolution

The collaborative Recrystallized Silicon Carbide plates now achieve thermal conductivity of 110-120 W/m·K (3× higher than alumina), with a perfectly balanced coefficient of thermal expansion (CTE) at 4.3×10⁻⁶/K.

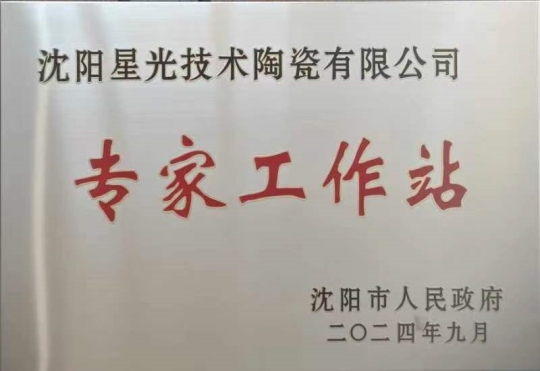

We are deeply honored that all the experts and professors have come to our company for guidance. Since its establishment, our company has maintained close exchanges and cooperation with many universities and research institutes.

We hope that with more exchanges and cooperation, we can continue to develop and innovate, leading the industry to excellence.

Get the latest price? We'll respond as soon as possible(within 12 hours)