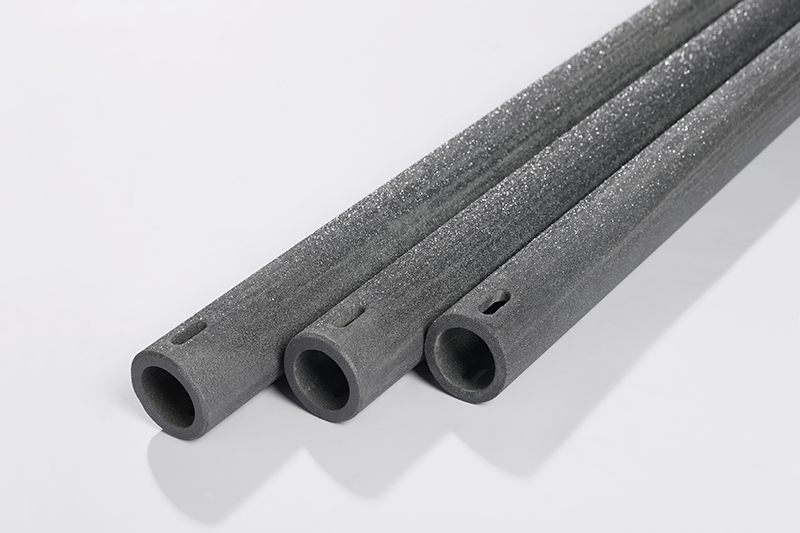

Recrystallized Silicon Carbide Roller

1. Our recrystallized silicon carbide roller has the characteristics of high purity and excellent wear-resistant.

2. Our recrystallized silicon carbide roller has high temperature and high load capacity.

3. Our recrystallized silicon carbide roller has good thermal shock resistance stability.

- STARLIGHT

- Shenyang, China

- Based on the quantity ordered by the product

- 500t/year

Details

Introduction to Recrystallized Silicon Carbide Roller:

Recrystallized silicon carbide roller is made by sintering high-purity and highly active silicon carbide raw materials in a vacuum induction furnace at high temperature of 2420℃.This type of Recrystallized Silicon Carbide Roller has excellent wear resistance, high temperature resistance, and corrosion resistance, and can be used for a long time at high temperatures up to 1650℃. Additionally, Recrystallized Silicon Carbide Rollers have excellent chemical stability and can resist the erosion of various acids, alkalis, salts, and other chemical substances. It is widely used in roller kiln and many kinds of kilns and furnaces.

Advantages of our Recrystallized Silicon Carbide Ceramic Roller:

Recrystallized Silicon Carbide Ceramic Roller can be used for a long time at high temperatures of 1650 ℃ and has good thermal stability.

Recrystallized Silicon Carbide Ceramic Roller has a hardness second only to diamond and excellent wear resistance.

Recrystallized Silicon Carbide Ceramic Roller has extremely high corrosion resistance to chemicals such as acids, bases, and salts.

Recrystallized Silicon Carbide Ceramic Roller has good flexural and compressive strength.

The service life of our Rsic Rollers is much longer than traditional materials, can significantly reduce replacement costs. So you can trustly choose our Rsic Rollers.

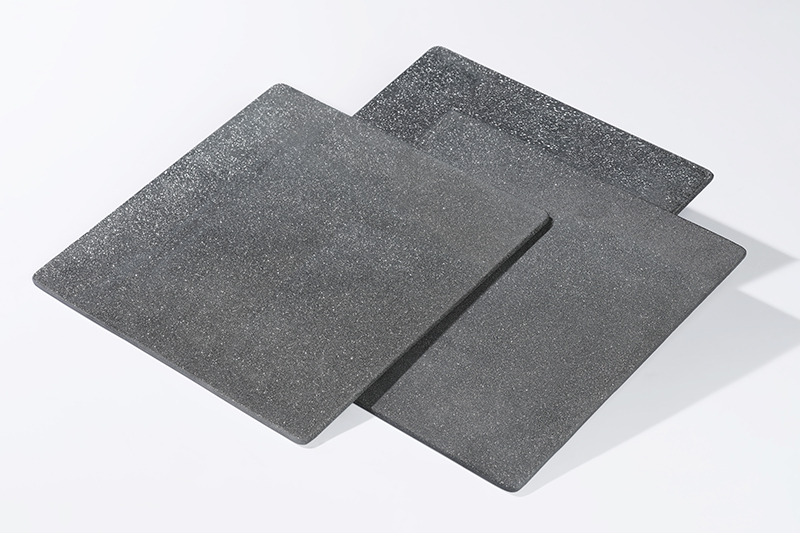

Application of our Rsic Rollers:

Our Rsic Rollers used in ceramic roller kilns can withstand high temperatures, heavy loads, and corrosive gases.

Our Rsic Rollers are used to manufacture conductive rods and high-temperature resistant components for electrolytic cells.

Our Rsic Rollers can be used as key components in glass furnaces, such as the furnace tubes and conveyor rollers of muffle furnaces.

Our Rsic Rollers are used to manufacture corrosion-resistant components such as high-temperature reactors, heat exchangers, and pipelines.

We have many customers are using our Rsic Rollers and with good feedback.

Regarding us:

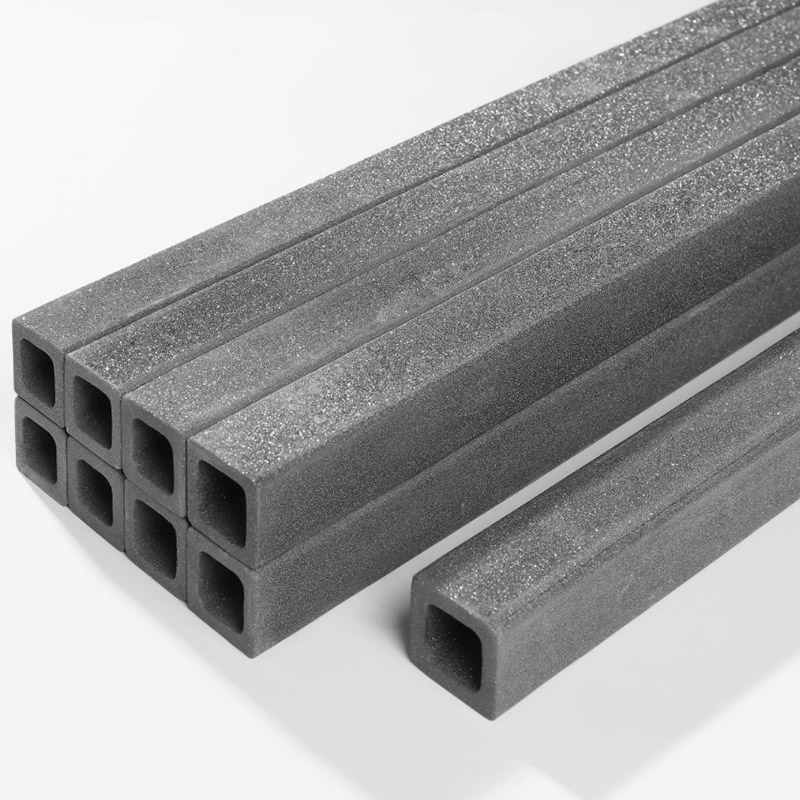

In the constantly changing era, Shenyang Starlight Advanced Ceramics Co., Ltd. has always maintained a forward-looking attitude to adapt to changes in market demand. As a new type of silicon carbide material manufacturing enterprise, Shenyang Starlight Advanced Ceramics Co., Ltd. closely integrates design, research and development, and manufacturing to form an industrial chain, winning market recognition and customer trust.We adhere to use our effect to be a leader of the silicon carbide insustry,create the value for both us and our customer.

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)