- Home

- >

- Case

- >

- Quartz Boat

- >

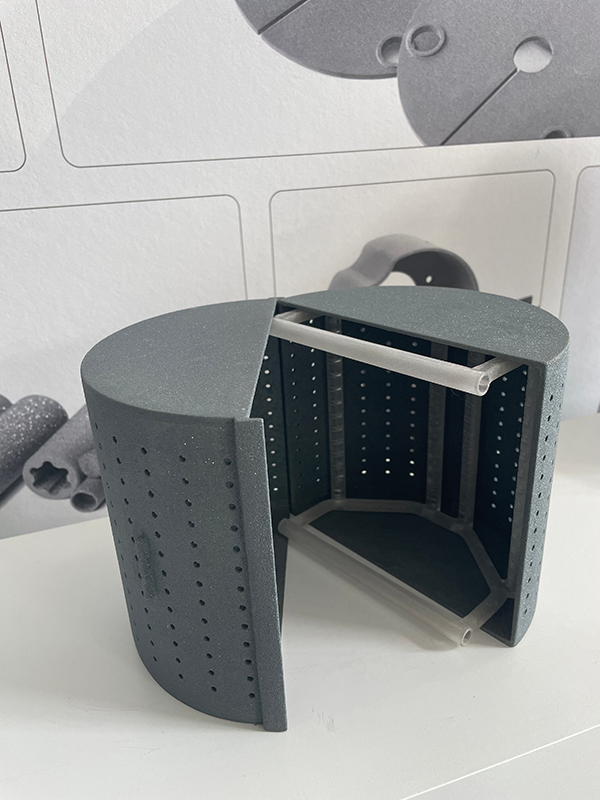

Quartz Boat

Shenyang Starlight Advanced Ceramics Achieves Breakthrough in Semiconductor Quartz Boat Manufacturing

Shenyang Starlight Advanced Ceramics Co., Ltd., a leading manufacturer of silicon carbide products with over 30 years of industry expertise, has successfully developed and delivered a high-performance quartz boat series for semiconductor wafer processing. This milestone underscores the company's capability to meet the stringent demands of advanced semiconductor manufacturing.

Innovation in Quartz Boat Technology

After years of rigorous R&D and testing, Shenyang Starlight has perfected its quartz boat series, specifically designed for wafer heat treatment in semiconductor fabrication. Key features include:

Ultra-high purity silicon carbide material, ensuring minimal contamination during high-temperature processes.

Exceptional thermal stability, capable of withstanding rapid thermal cycling up to 1,200°C.

Precision-engineered structural integrity, preventing wafer warping or damage during processing.

These silicon carbide quartz boats are critical for wafer annealing, diffusion, and oxidation processes, where material purity and thermal performance are paramount.

Meeting Semiconductor Industry Demands

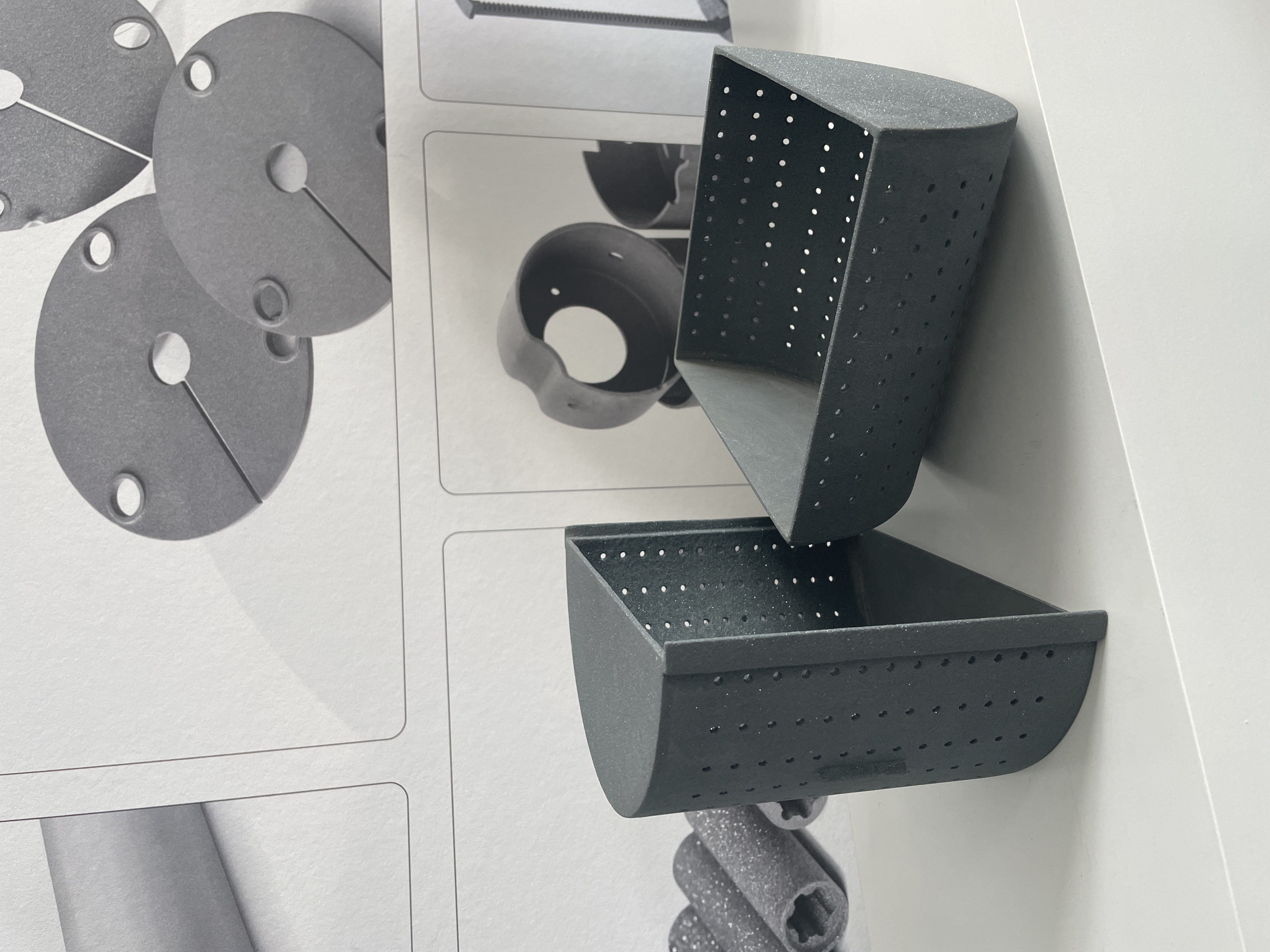

Semiconductor manufacturers require consistent, contamination-free handling solutions for delicate silicon wafers. Shenyang Starlight's silicon carbide quartz boats address these needs by offering:

Superior chemical resistance to corrosive gases used in deposition and etching.

Optimized design for uniform heat distribution, reducing wafer stress.

Long service life, lowering total cost of ownership for semiconductor fabs.

"Our silicon carbide quartz boat series represents years of material science refinement," said a company spokesperson. "We've combined high-purity quartz and silicon carbide with precision manufacturing to deliver a product that meets the exacting standards of semiconductor production."

R&D and Quality Assurance

Shenyang Starlight's success stems from its:

Dedicated R&D team, collaborating with leading academic institutions.

Advanced testing protocols, including thermal shock resistance and particle emission analysis.

ISO 9001-certified production, ensuring batch-to-batch consistency.

The company's quartz boats have undergone extensive qualification testing in partnership with semiconductor equipment manufacturers, confirming the silicon carbide products reliability in real-world applications.

Applications in Wafer Fabrication

The quartz boat series is now being adopted for:

Front-end wafer processing (e.g., oxidation, doping).

Back-end annealing for advanced packaging.

Photovoltaic cell manufacturing, where high-temperature stability is crucial.

Future Developments

Building on this success, Shenyang Starlight is expanding its semiconductor ceramics portfolio, with ongoing projects in:

Silicon carbide-coated quartz components for enhanced durability.

Customized boat designs for next-gen wafer sizes.

Low-particle emission materials for EUV lithography compatibility.

Commitment to Semiconductor Excellence

"Semiconductor manufacturing is evolving rapidly, and we're committed to providing cutting-edge ceramic solutions that enable our clients’ success," the spokesperson added.

Get the latest price? We'll respond as soon as possible(within 12 hours)